Wallcoverings are the darling of the home furnishing industry and the beauty artifact of the monotonous white walls. However, as a textile, wallcoverings will inevitably have weft skew problems, which often bring trouble to construction. What is the weft skewness of the wall? How to deal with wallcovering weft skewness? Today we will talk about the wallcovering weft skewness problem.

What is weft skewness

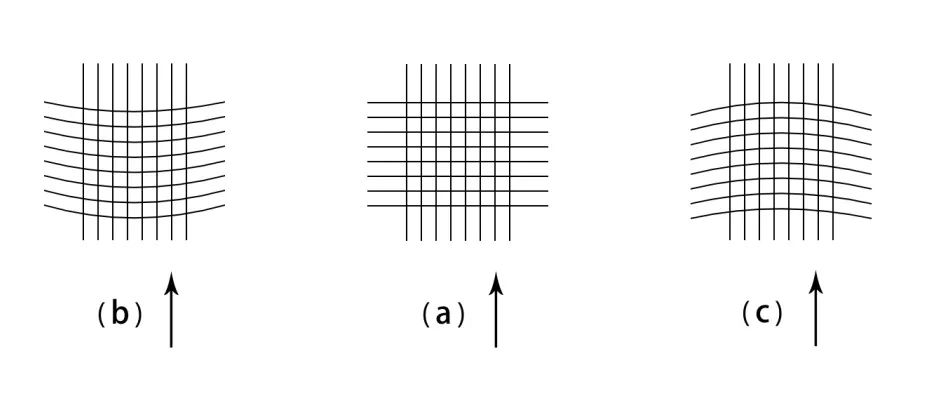

The definition of weft skewness: the fabric structure of the fabric and the fabric fibers of the knitted fabric are inclined, or the fabric structure is twisted. This phenomenon is called weft skew.

Typical case of weft skewess

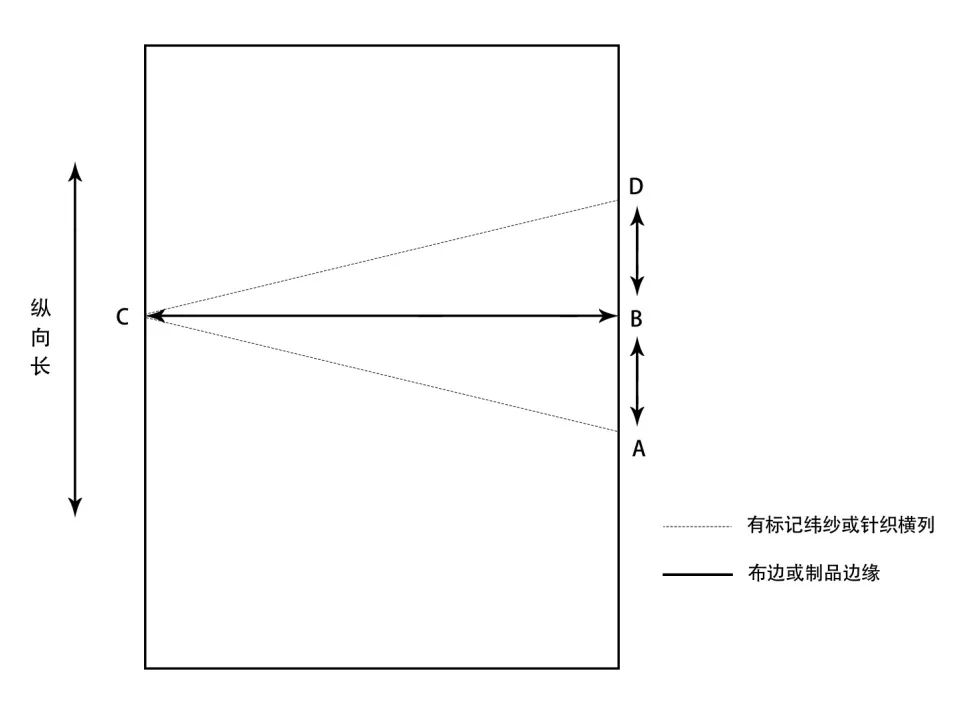

According to "GB/T 14801-2009", the calculation formula of weft skew is: S=D/W*100

Type:

S——Weft slope (%)

D——The vertical distance AB or BD between the weft row and the ruler, mm

W——fabric width or product measurement part width BC, mm

♥Tip

According to "JG/T510-2016", the weft deviation of seamless wallcovering is less than 1.5% is qualified.

Causes of weft skewness

There are generally two reasons for the weft deviation of textiles. One is that in the textile manufacturing process, the weft deviation is caused by the large internal stress caused by improper handling. The second is caused by improper tension adjustment in the post-processing of textiles, such as dyeing and printing.

The weft bias of the wallcovering is similar to the second type, which is generally produced in the composite processing process. Because the width of the wallcovering is very wide, the tension on both sides of the roller is different from that in the middle when passing through the laminating machine. After the lamination is completed, the edge and center will deviate, resulting in weft skew.

Wallcoverings with too large weft slope are defective products, and the weft slope increases the difficulty of wallcovering construction to a certain extent. If the construction did not deal with the weft skew problem, will affect the overall effect of the wallcovering on the wall, so that the wallcovering pattern is not neat enough, affect the appearance, especially the effect of the vertical stripe wallcovering is especially obvious.

Although the weft skew problem is inevitable, it is controllable. In terms of the control of weft skew in the subsequent process, the hot glue process has sufficient advantages over the cold glue process.

Cold glue wallcovering:

For cold glue wallcovering, the greige cloth must be compounded with non-woven fabric. The whole process of compounding cannot be stopped, and the width of the fabric is generally about 3m. Once the roll is running fast, it is easy to cause the two sides in the width direction to run in the middle. Once the embryo fabric is compounded with the underlying non-woven fabric, an irreversible weft skew problem is formed.

hot glue wallcovering

As for the hot glue wallcovering, a layer of hot melt adhesive film is directly applied on the back of the greige cloth by using the segmented compounding equipment. Due to the segmented compounding, the whole compounding process is easier to control. Once the weft skew problem occurs, it can be made as soon as possible Adjust to reduce the weft slope of the finished wallcovering.

The solution to weft skewness

In the process of wallcovering production, the use of the old-fashioned roller laminating machine is abandoned, and the use of segmented pressing technology can better control the weft and skew problems generated in the lamination process.

If you encounter a wallcovering with a serious weft during use, you can avoid it by using the inner corner of the wall. When the wallcovering is constructed to the inner corner, be sure to cut the wallcovering at the inner corner! Although the integrity of the wallcovering is destroyed, this can minimize the weft skew.

The width of the wallcovering is generally 3 meters, and the floor height of the home is mostly about 2.6 to 2.7. It is recommended that the construction master can cut off the more serious parts on both sides, and take the middle section for construction, which is relatively better.